A year of data and one clear message: Permian flaring remains a major problem

By Colin Leyden and Ben Hmiel

By Colin Leyden and Ben Hmiel

Even amidst a global pandemic and market volatility that reduced oil and gas activity, at least one thing didn’t change in the Permian last year: operators can’t seem to keep their flares lit.

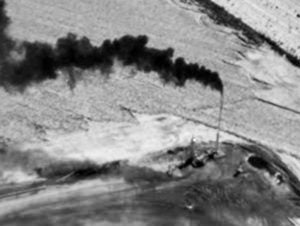

Throughout 2020, EDF conducted aerial surveys of portions of the Permian Basin to determine the performance of natural gas flares. Even when done properly, flaring is a wasteful, polluting practice that has earned industry “a black eye.” But when flares malfunction they also become major sources of highly potent, climate-polluting methane.

Over the course of 2020, we conducted periodic surveys of flares in various parts of the Permian. These took place in February, March, June and November, and included a series of consecutive, repeat surveys of one specific area on November 2, 4 and 6 meant to understand how long flare malfunctions persist. In total, we studied nearly 1,200 flares in the region.

Together, these surveys underscore that the oil and gas industry won’t solve its methane problem until it solves its flaring problem, which is likely responsible for 10% or more of the industry’s total methane emissions across the Permian — a region that peer-reviewed data shows emits three times more methane than EPA data suggests. Unchecked flaring failure — in addition to the practice of routine flaring — is compounding industry’s challenges at a time when investors, the public and global markets are calling for cleaner products and the Permian’s emissions are attracting international attention.

Across the year’s surveys, we consistently found that roughly 10% of all flares were malfunctioning. Approximately 5% of all flares were entirely unlit and releasing unburned methane directly into the atmosphere. Percentages varied slightly by location, ownership and other variables, but it’s safe to say that malfunctioning or unlit flares are a problem everywhere and for everyone in the Permian.

Explore the data on PermianMAP.org and via this infographic.

During our final survey in November, we wanted to better understand the persistence of malfunctioning flares. By revisiting all flares in a ~200km2 area multiple times during the week, we were better able to determine whether a malfunctioning flare was just “having a bad day” or was persistently malfunctioning. Of the malfunctioning flares we observed, more than half were unlit or partially lit on multiple days during the week. A quarter of these never functioned properly while we were present.

The fact that flares are consistently malfunctioning and those malfunctions appear to be persisting is an alarming sign that companies or regulators are not doing enough to maintain basic performance standards.

Keeping your flares lit is an extremely low bar. And it’s important to note that keeping all flares lit would only reduce part of the problem. Flaring is certainly better than venting unburned methane straight into the atmosphere. But even when operating properly, flaring is a dirty and wasteful way to manage excess gas.

Ending routine flaring altogether and working to reduce unplanned event flaring is the most straightforward solution. It would reduce pollution, save a valuable product and natural resource, and re-align the Texas industry with what investors and global consumers are demanding. A recent analysis by Rystad Energy found that requiring operators to capture (and not flare) 98% of the gas that is produced by wells would eliminate 84% of routine flaring volumes and 40% of total flared volumes in the Permian at no cost and result in an additional $400 million of wellhead value by 2025.

New Mexico’s Oil Conservation Division is moving forward with a set of rules that would end routine flaring and address the issue of methane waste, and Colorado has already enacted rules to end routine flaring. These measures are cost-effective and increasingly critical for industry to compete in an economy that places a premium on cleaner fuels.

There will always be some minimal necessity to flare for health and safety reasons, underscoring the need for solutions to tackle malfunctioning flares. We need more frequent industry monitoring and regulatory inspections, along with requirements for auto-igniters or enclosed combustors, which would each make a meaningful impact. Texas could also incentivize the use of super-high efficiency flares beyond the current 98% efficiency requirement.

Industry’s flaring problem is clear, as are the solutions regulators and operators can use to mitigate it — and the data confirm that voluntary efforts alone are insufficient for tackling this challenge. Recent comments from Railroad Commission Chairman, Wayne Christian, supporting an eventual end to routine flaring in Texas are encouraging, but this needs to be followed up with a tangible regulatory pathway toward ending the practice. Whether regulators and operators will address flaring head-on will determine how Texas energy companies fare in coming years.