ASDWA provides new recommendations to states and utilities for lead service line inventories

Tom Neltner, J.D., Chemicals Policy Director

The Association of State Drinking Water Administrators (ASDWA) released a new white paper to help states and utilities develop more useful inventories of lead service lines (LSLs). The paper builds on guidance the organization issued in August 2019. ASDWA partnered with BlueConduit to leverage that firm’s experience developing a statistical model for Flint, Michigan that accurately predicted which service lines were made of lead, galvanized steel, plastic or copper.

The guidance is timely as EPA prepares to finalize its Lead and Copper Rule revisions. We anticipate those revisions will require utilities to develop – and make public – inventories that identify the location of each service line made of lead or when the material is unknown and may be lead. Utilities would also be required to notify customers annually if they have a lead or unknown service line. Customers who buy a home and open a new water account would also be notified in the first bill.

The ASDWA/BlueConduit white paper encourages utilities to use five principles to best characterize the uncertainty in their inventories:

- Ensuring clean data management and organization;

- Not accepting all historical records as truth;

- Conducting a representative randomized sample of unverified service lines;

- Being transparent in public outreach and reproducibility; and

- Demonstrating accuracy on “hold-out sample.”

The principles include randomly selecting a sample of service lines with unknown materials and inspecting them to determine if they contained lead or galvanized steel pipe. Large systems would need to inspect around 400 locations. The results of the inspection generate a statistically sufficient estimate of the total number of lead or galvanized steel pipes in the service area and provide a powerful tool to estimate the likelihood of finding lead or galvanized at each pipe.

The white paper includes the following recommendations for utilities:

- Creating a spreadsheet or database that tracks each service line and all associated data;

- Incorporating historical records into analysis but not using those records as definitive evidence of presence or absence of lead;

- Verifying materials of a representative random sample of “unknown” service lines;

- Predicting the likelihood of a service line being lead (or galvanized) based on the random sample, historical records, and ongoing inspections;

- Holding-out some of the service lines from the information used to develop a predictive model so they can be used to evaluate the model’s accuracy and prompt any refinements;

- Being transparent with the state, customers, and the public about the analysis; and

- Using the model to develop and manage LSL replacement programs, prepare funding requests, and comply with state and federal rules.

For ASDWA’s members, the paper recommends:

- Encouraging utilities to set up inventories in clear and accessible ways and making the information publicly available through online interactive maps and downloadable spreadsheets;

- Developing a statewide template for utilities to use to collect and submit the data;

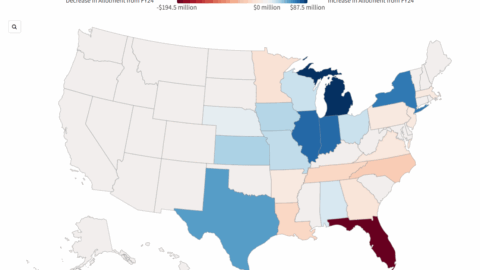

- Using the inventories provided by utilities to develop statewide inventories that shape policy priorities, including evaluating funding needs;

- Using best practices for public health communications to address uncertainties regarding the service line materials; and

- Offering workshops and guidance on best practices.

We applaud ASDWA and BlueConduit for the thoughtful guidance and encourage states and utilities to use it as they develop their LSL replacement programs.