Richard Denison, Ph.D., is a Senior Scientist.

I had reported in an earlier post – based on data provided to EPA by Nalco, the maker of Corexit® 9500, the main dispersant being used in the Gulf – that the dispersant appeared to increase the acute aquatic toxicity of oil.

At a press conference today, EPA released data from the second round of its own testing on Corexit 9500 (and seven other dispersants), and concluded that the acute toxicity of the dispersant-oil mixture is about the same as the oil by itself.

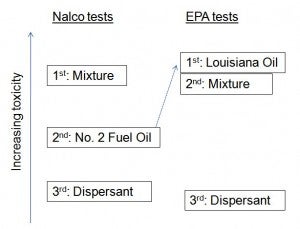

What explains the discrepancy? To put it most simply: It’s not that the dispersant-oil mixture was less toxic in the EPA tests, it’s that the oil EPA used – which is the actual oil that has been leaking into the Gulf – was more toxic than the fuel oil Nalco had used. Here’s a cartoon illustrating what I’m saying (the arrow shows the biggest change):

So the good news is that the dispersant doesn’t appear to be increasing the acute aquatic toxicity of the oil released into the Gulf. The bad news is that the oil is pretty toxic, and the dispersant certainly doesn’t help directly with that. And of course, the bigger questions about longer-term effects of dispersants and dispersed oil are not addressed by the new data.

Here’s more detail on the new data EPA released today and how they compare to the earlier data submitted by Nalco.

The biggest reason for the difference in the two sets of tests is that Louisiana sweet crude oil is quite a bit more acutely toxic by itself than is the No. 2 fuel oil used in the standardized test Nalco used: 4- to 6-fold more toxic.

The toxicity of the dispersant-oil mixture, in contrast, was much more similar in the two sets of tests, differing by only a factor of 2 to 3. (EPA regards values differing by a factor of 3 or less not to be significantly different.)

The first tests conducted by Nalco using No. 2 fuel oil found that the dispersant-oil mixture was 4- to 5-fold more toxic than the oil by itself.

The new tests conducted by EPA using Louisiana sweet crude oil (obviously a more relevant oil to use to mimic the conditions of the BP oil disaster) found that the dispersant-oil mixture was only 2- to 3-fold less toxic than the oil by itself. (Again, EPA regards values differing by a factor of 3 or less not to be significantly different.)

| LC50* values in parts per million (ppm) | |||||

| Menidia (inland silverside fish) 96-hour test |

Mysidopsis (mysid shrimp) 48-hour test |

||||

| EPA test of Corexit® EC9500A using Louisiana sweet crude oil (LSC) | Dispersant alone | 130 | 42 | ||

| LSC alone | >2.9 | Mixture is <2.6 x less toxic than LSC alone | 2.7 | Mixture is 2.6 x less toxic than LSC alone | |

| Dispersant : LSC (1 : 10) | 7.6 | 5.4 | |||

| Nalco test of Corexit® EC9500A using No. 2 fuel oil (per NCP Product Schedule protocol) | Dispersant alone | 25.2 | 14.6 | ||

| No. 2 fuel oil alone | 10.7 | Mixture is 4.1 x more toxic than No. 2 alone | 16.1 | Mixture is 4.7 x more toxic than No. 2 alone | |

| Dispersant : oil (1 : 10) | 2.6 | 3.4 | |||

| Ratio of EPA to Nalco data | Dispersant alone | 5.2 x lower toxicity | 2.9 x lower toxicity | ||

| Oilalone | <3.7 x higher toxicity | 6.0 x higher toxicity | |||

| Dispersant : oil (1:10) | 2.9 x lower toxicity | 1.6 x lower toxicity | |||

| *LC50 = concentration at which 50% of the test organisms are killed within the duration of the test. NOTE: higher value = less toxic; values differing by <3-fold are not considered significantly different | |||||

4 Comments

“The bad news is that the oil is pretty toxic, and the dispersant certainly doesn’t help directly with that.”

Isn’t it a little unrealistic to expect the dispersant to reduce the toxicity of the oil?

Yes, Bob — my point was that the dispersant appears largely to be irrelevant with respect to at least acute aquatic toxicity. So the larger questions about either more subtle toxicity changes or impacts associated with the wholly altered fate and transport of the dispersed oil — which are largely unknowns at this stage — are likely to be the more important issues.

Richard

I recall reading someone’s feeback to an article on CNN some time ago on the Gulf oil spill, where they had claimed that a glass of water emptied into the ocean would become globally distributed within 7 days due to the mobility of the ocean currents. I am not sure of the validity of this statement, as there must be many differences due to landmass, water temperatures, etc. However, if the oil is treated and becomes chemically dispersed, it seems like this could adversely affect (increase) the rate at which the oil spreads. Ultimately, this would increase the effort needed for recovery as well as the contact with wildlife/humans. Do you have any comments on this?

Richard,

Excellent observation concerning the Nalco/EPA test standard using #2 Oil, which has already been through a refinery process anyway.

One thing al lot of media and EPA/NOAA and other testing agencies have not addresses and even when requested to comment on refuse. Is the following:

(A) the leak occurred at 5,000 feet and a surrounding pressure in the water of 2,188.3 PSIG and approx freezing.

(B) the Well leak was coming out at around 7,200 to 8,400 PSIG and somewhere between 285 to 350 F via a 21″ diameter pipe partially blocked by the drill pipe and the cracks/ruptures in the piping/top-hat.

(C) taking A&B above the fluid coming out is a mixture of Crude Oil, Hydrates, Methan Gases (reason for varying pressure)plus sea water. So you have a High-pressure Aerosolized Hydro-Emulsified mixture which is exposed to a (lets say 6,000 PSIG differntial and 230 F temp differntial as well) big explosive environment and chemical poymerization occurring.

(D) NOW add in the Corexit 9500 and 9527 mixture at 15,000 gpd and 2% by volume of Methanol of the Corexit mix to this explosive environment….what has really occured with all these different volatiles at such high pressure and temeperature. Remember 9527 contains 2-Butoxyethanol as well as the other ingredients of 9500. Several people have tried to evaluate the mix reaction on the base material structures at the Mol and Atomic level….keep saying yes there is OIl but the rest is a Witches Brew and keeps moving around.

So why does the EPA keep insisting along with other agencies nothing is wrong , when the Exxon Valdez reports and others have shown differnt results. Plus the EPA pulled Corexit 9555 of there list as being too toxic on June 10th 2010, yet let BP use it with 9527 for aerial spraying.

Please comment on the above as I feel it will add to your well addressed comment about Nalco/EPA test methods.

Ther are numerous documented medical reports on the internal bleeding by the workers exposed on the water and shorelines… one of the effects from exposure to Corexit 9527/9555 containing 2-butoxyethanol