Mapping the maze: data reveals the need for protective standards for all gas gathering pipelines

By Magdalen Sullivan & Kate Roberts

As the U.S. oil and gas industry expands, the vast network of largely unregulated pipelines that transport unprocessed natural gas —known as gathering pipelines — has crept closer and closer to residential communities. Most gathering pipelines are currently exempt from regular inspection, which means that leaks and other problems in these pipes can, and routinely do, go undetected.

A new report, however, reveals that unregulated pipelines can be embedded in communities, putting residents at risk due to the lack of safety standards that apply to this aging infrastructure that transports an explosive fuel. The report also illustrates that under the current patchwork of federal standards, regular leak monitoring and repair may be required on one pipeline segment, but no protections apply on another segment just a few yards away. The Pipeline and Hazardous Materials Safety Administration, or PHMSA, should rapidly adopt proposed federal standards that will expand advanced leak detection and repair practices on U.S. gas pipelines. All gas gathering pipelines should be subject to such rigorous oversight.

Mapping the maze: data reveals the need for protective standards for all gas gathering pipelines Share on XHealth, safety and climate concerns

Currently spanning over 430,000 miles in the U.S., gathering pipelines transport unprocessed gas from production sites to processing facilities. Leaks on these systems pose particular risks because unprocessed gas contains a mixture of methane and harmful air pollutants, including volatile organic compounds, known as VOCs, and benzene. Exposure to these pollutants can have severe health implications. In addition to the health risks, gathering pipelines can cause devastating safety incidents that harm nearby communities.

Gathering line leaks also emit large amounts of methane, a potent greenhouse gas with more than 80 times the warming power of carbon dioxide over the first 20 years after it reaches the atmosphere. One study estimated that gathering pipelines in the Permian Basin leak 213,000 metric tons of methane per year — the equivalent climate impact of almost 4 million gas-powered passenger vehicles.

An oversight gap

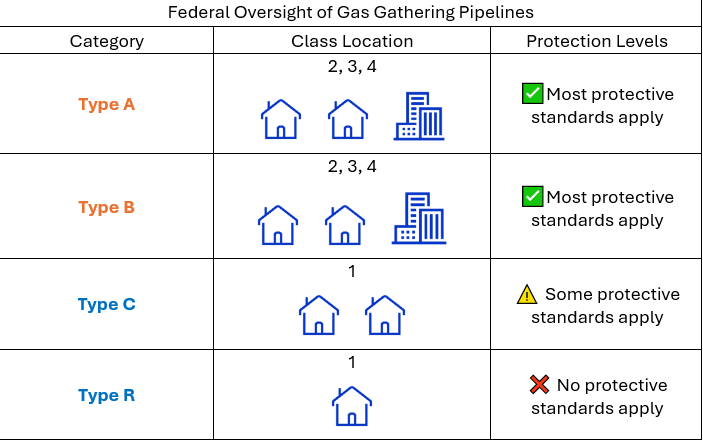

PHMSA, the federal agency tasked with ensuring the safety and environmental integrity of natural gas pipelines, has established a tiered approach to pipeline oversight. The four different types of gathering pipelines are subject to different levels of oversight, based on the pipeline’s proximity to nearby buildings — known as Class Location — as well as other factors like pipeline material, pressure and size.

Most Type C and all Type R pipelines are not subject to federal safety standards because they are located in more rural areas. This means that over 90% of gathering pipelines in the US aren’t required to check for leaks.

PHMSA has proposed much-needed protections, including expanding advanced leak detection and repair standards to all Type C gathering pipelines, about 90,000 miles.

Industry critics of the proposed rule have asserted that Type C and R gathering lines should not be subject to leak detection and repair requirements, claiming they are inherently different than Type A and B pipelines. A review of pipeline data shows that this argument is unfounded.

Interconnected pipelines, different standards

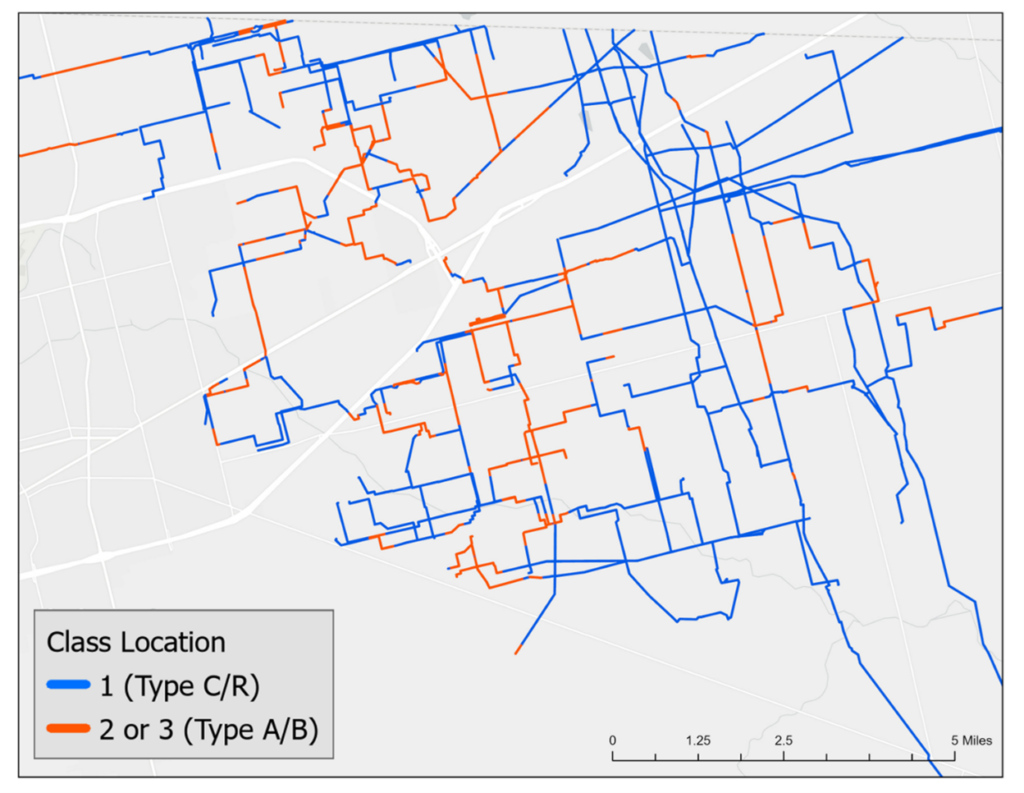

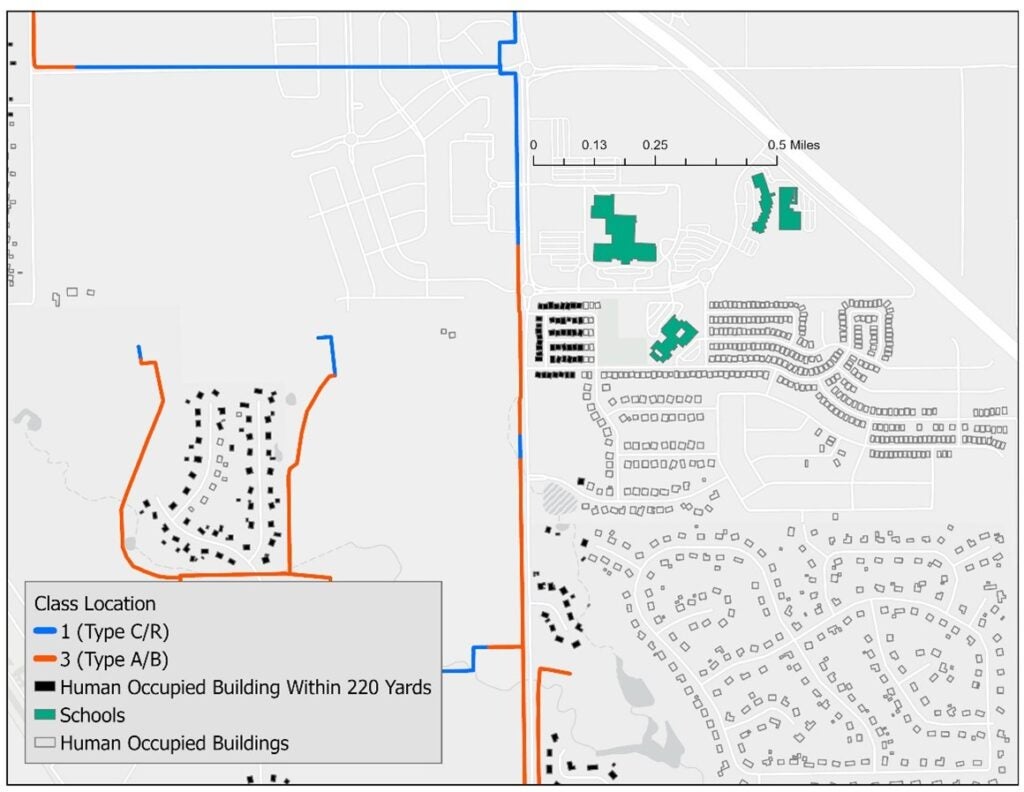

An analysis of publicly available data from the Texas Railroad Commission, also known as the RRC, reveals that gathering pipelines often switch regulatory status several times within the same community. That means a single pipeline can shift from being monitored by operators to not, or vice versa, within yards.

The analysis reviewed 415 miles of sample pipelines based on RRC pipeline data. The Type A/B segments are subject to federal leak repair standards, while the Type C/R segments may be completely unregulated.

Methane leak surveys are often conducted by plane or helicopter for gathering pipelines, with a sample flight route from a past aerial methane survey shown below. If an operator is already surveying Type A and B pipelines, it is practical and cost-effective to check for leaks on the Type C and R pipelines nearby. All gathering pipelines should have to meet robust safety and environmental standards, to keep communities safe.

Health consequences of gas gathering infrastructure

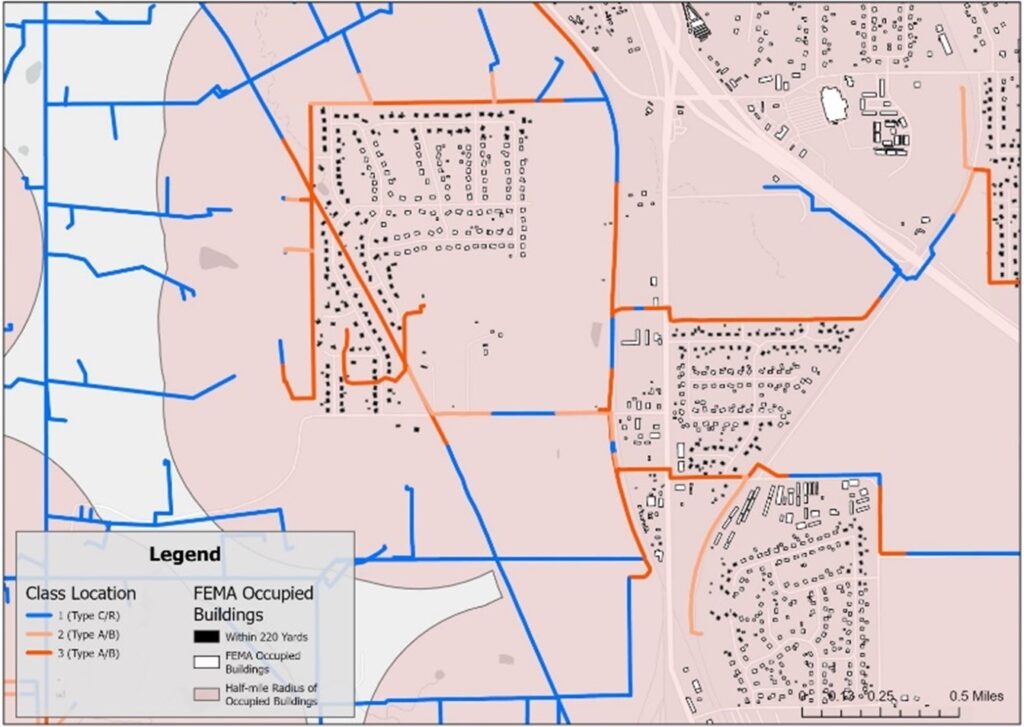

Epidemiological studies have found that people living within half a mile of gas production activities are at risk of negative health impacts due to the air pollutants in unprocessed natural gas. But gathering pipelines located within a half-mile of homes and occupied buildings are not all required to find and fix leaks under current federal standards.

In the mapped area, many homes were located within a half mile of Type C or R gathering pipelines that are subject to minimal standards or unregulated.

In one instance, three schools are located within a half mile of a 16-inch diameter Type C pipeline.

Conducting leak surveys and repairs on all gathering pipelines can benefit human health by reducing harmful pollution for communities near pipeline networks.

One pipeline, 21 Changes in Monitoring Requirements

Not only are pipelines of different types located right next to each other, but the same pipeline can change regulatory categories many times over very short distances. The analysis found that one pipeline switched between different federal monitoring requirements 21 times over the course of 13 miles. On average, it changed class location every half mile or so. In some sections, however, different federal standards apply to segments less than 100 meters in length. It is challenging to imagine an operator only doing leak surveys and repairs on every other segment of a pipeline like this — the practical, safer and more environmentally protective approach would be to survey the entire length for leaks.

PHMSA’s proposed rule is a major step forward

The proposed Advanced Leak Detection & Repair rule will institute much-needed protections to improve pipeline oversight and reduce pollution from the nation’s network of natural gas pipelines, requiring leak detection and repair for all Type C gathering pipelines for the first time. PHMSA should swiftly finalize robust safety standards for this sprawling infrastructure.

Current and proposed standards, however, are still less protective for Type C and R gathering pipelines compared to other categories. And the varying levels of oversight can result in lower levels of protections applying to segments of the same pipeline, by a matter of feet. Operators can and should be required to find and fix leaks on all gas gathering pipelines.

The analysis presents Class Locations for representative pipeline segments, and the possible applicable regulatory categories (Types A, B, C, R) – the precise regulatory categories are not always identified because the relevant pipeline diameter and pressure data is not publicly available.