Experts weigh in: we need to learn about chemicals in oilfield wastewater before reusing it outside the oilfield

A recent publication of the Air and Waste Management Association (AMWA) contained a number of articles by academia and industry experts about the many challenges of managing the nearly 900 billion gallons of wastewater (also called produced water) generated every year by oil and gas production. This wastewater is not only very salty but also contains a number of chemicals (many toxic) and potentially radioactive material.

The majority of this wastewater is disposed in deep underground wells to minimize the risks of it coming into contact with humans or the environment (though leaks and spills at the surface are still a big concern). But in hope of lowering costs, in recent years industry has been trending toward finding other ways to either dispose of or recycle this waste – in part because demand for water resources is increasing in drought prone areas and because disposal wells have been linked to a rise in earthquakes.

The articles in AWMA’s magazine suggest that recycling oilfield wastewater to complete new wells is the most viable alternative to traditional disposal methods. Definitely more viable than reusing this water in other ways outside oil and gas operations.

Hydraulic fracturing is a water intensive process. Fracturing just one well can require up to 15 million gallons of water. On the back end, every one barrel of oil produced can produce up to 10 barrels or more of wastewater. Consequently recycling this wastewater for hydraulic fracturing other wells can make a lot of sense.

In this latest issue, Rick McCurdy, who manages corrosion, chemicals and water with Chesapeake Energy Company, presents the various technical and economic issues with recycling oil and gas wastewater instead of disposing of it underground. He points out that recycling this wastewater replaces the need to purchase an equal volume of fresh water. Under the right conditions, this recycling “can provide a cost savings over conventional, commercial disposal, and a reduction of stress on local water availability in areas prone to drought.”

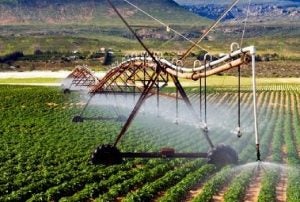

This could be a positive development in regions experiencing drought conditions, but experts are advising companies not be too eager to use this water for activities beyond the oil field – like crop irrigation, or livestock watering for example.

“Due to the high concentrations of TDS (total dissolved solids) along with other constituents of concern, reuse options of produced water outside the oil industry, such as streamflow augmentation or irrigation, will most likely require robust treatment including desalination,” according to Emily Nichols, an engineering graduate fellow in the Colorado School of Mines.

Not only is desalinating water extremely costly, in many cases we lack the data to know — with assurance — that water has been treated to reach levels that are clean enough to be used for crops or livestock.

“To answer this question, assessments of the chemical risks of reusing produced water must be undertaken,” write Dr. Dominic DiGiulio and Dr. Seth Shonkoff of the group Physicians, Scientists and Engineers for Healthy Energy (PSE Healthy Energy).

Studies have found that even treated wastewater can still contain trace amounts of harmful chemicals — indicating that our current treatment technologies, especially lower cost technologies, may not be advanced enough to guarantee water quality that is truly fit-for-purpose.

Recycling within the oil field is a great idea as long as the wastewater is not spilled. But researchers argue that more disclosure about the chemicals used in hydraulic fracturing, more chemical analysis, improved chemical monitoring technology and better toxicity assessments are needed before expanding reuse options outside of the oilfield. Without these advancements, experts agree reusing wastewater for non-industry related purposes is both cost-prohibitive and exceptionally risky.